Serious Technology…

And serious experts. We are industry veterans who know our machines, materials and processes inside and out. Proudly based in New York, NY.

Serious Technology…

And serious experts. We are industry veterans who know our machines, materials and processes inside and out. Proudly based in New York, NY.

Bring your ideas to life

At Obsessively Geek, we are a team of industry experts here to make your ideas a reality. We are a full service company. From 3D Printing, to laser cutting, to painting, to post processing, we have all your needs covered. Made in the USA.

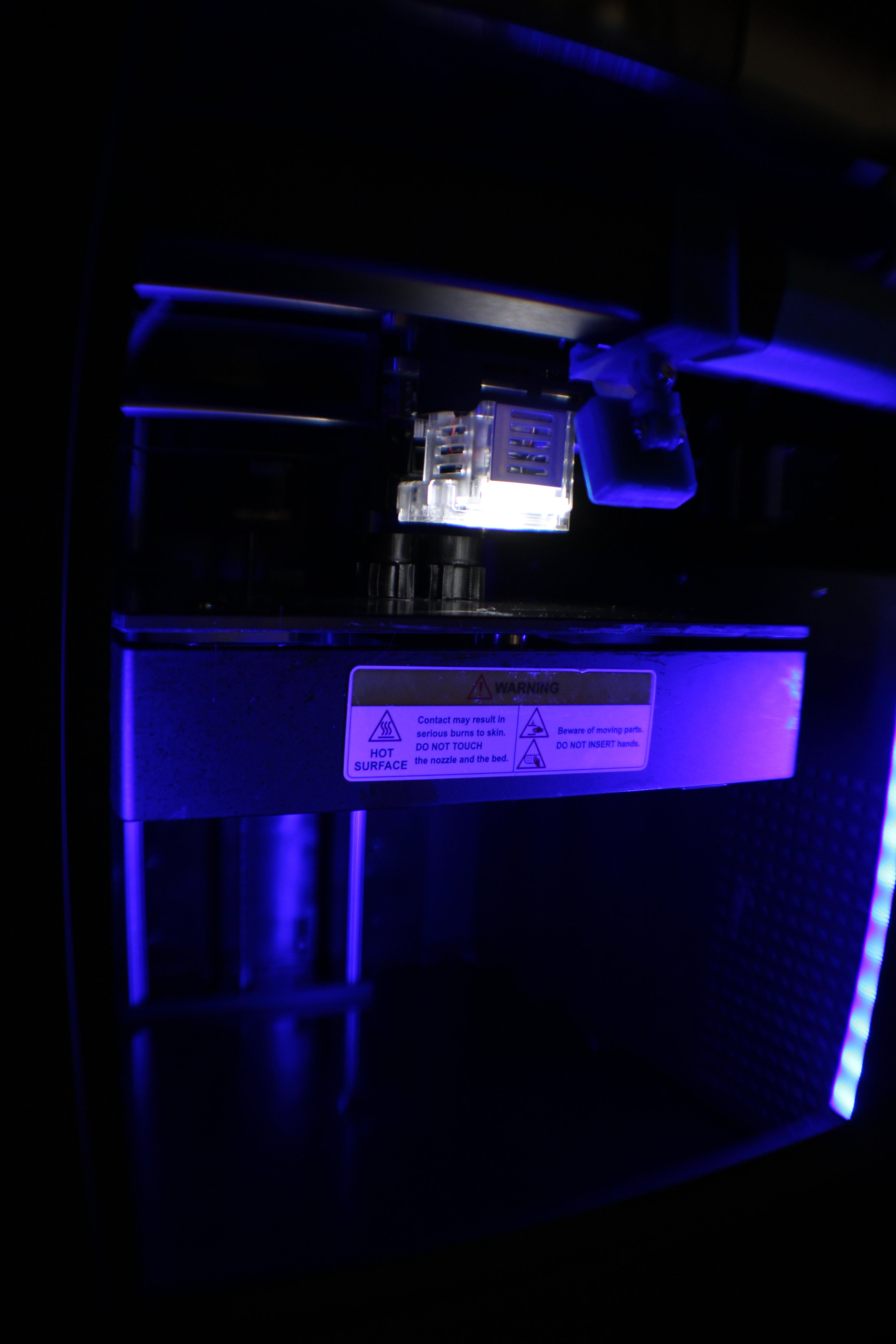

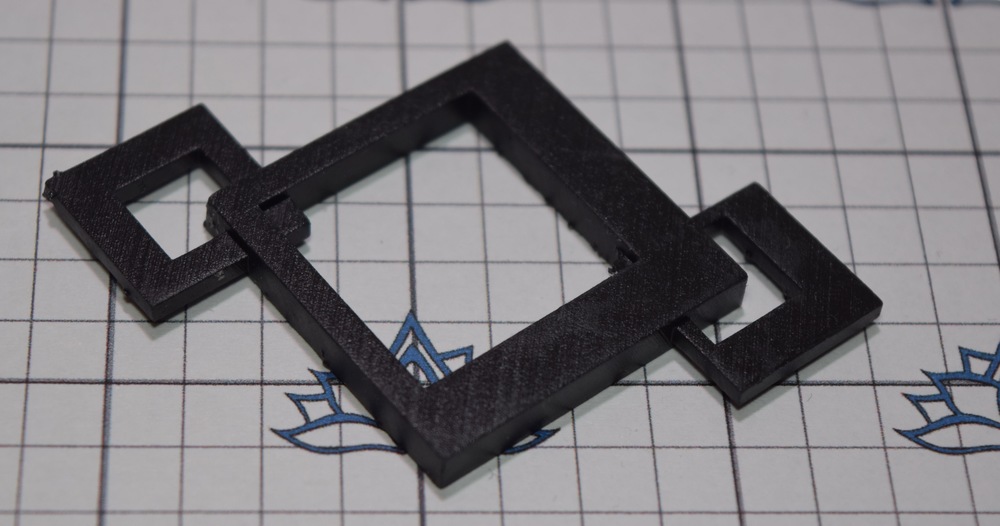

FDM 3D Printing

FDM 3D Printing is what most people think of when they think of 3D Printing. Plastic filament is melted and pushed through a hot nozzle on to a build plate layer by layer to create your part. Because of the process and materials of this 3D Printing method layer lines are visible on parts produced. This is usually used for earlier prototypes, parts that need a lot of revisions, or parts that need a specific thermoplastic for engineering or high stress applications. It is also normally one of the most affordable forms of 3D Printing.

Polyjet 3D Printing

Polyjet 3D Printing most closely resembles inkjet 2D Printing. A head squirts out various resins on to a build plate which then hardens using a UV light like in SLA. It excels at making multimaterial 3D Prints where mixed materials are needed. For example a helmet where the outside needs to be hard and the inside needs to be soft. Parts can come out looking like almost completely finished products from this process.

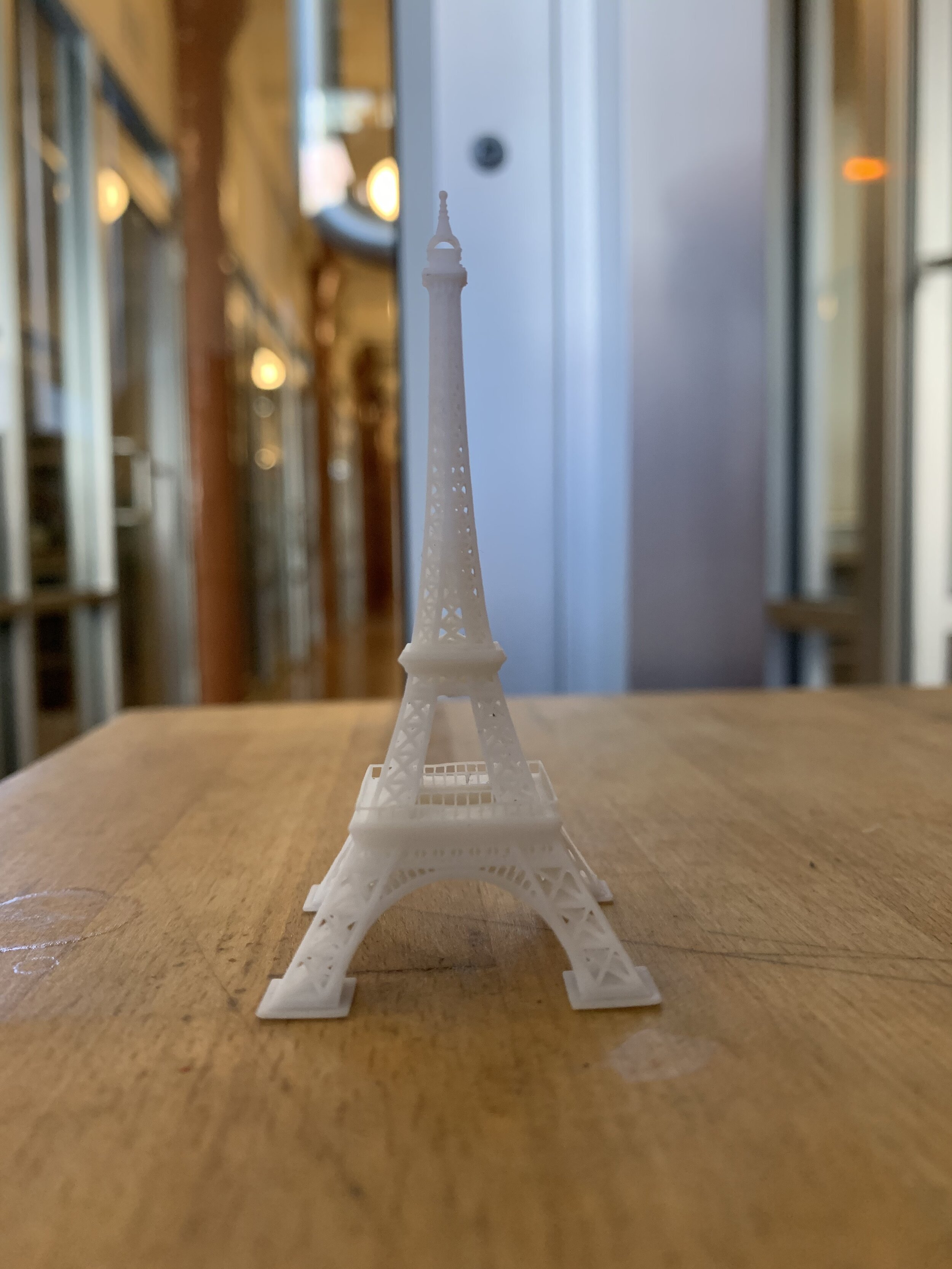

SLA & DLP 3D Printing

SLA 3D Printing uses a UV layer to harden a photosensitive liquid resin into actual parts. This process is again done layer by layer, however due to the high precision of lasers and laser systems these parts can look a lot more finished than FDM 3D Printed parts. These parts are usually used for parts that need less revisions, more detail, or need to be very visually appealing. Can also produce castable wax parts for casting metals such as jewelry.

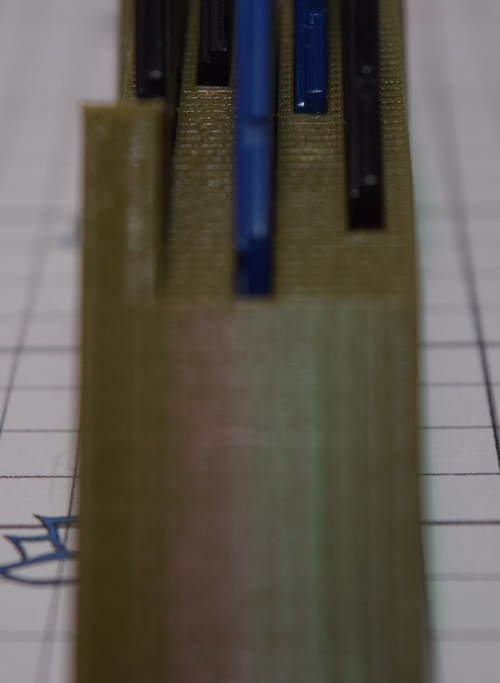

Laser Cutting

Unlike 3D Printing which is additive manufacturing (you add material to create parts) laser cutting is subtractive manufacturing (you remove material to create parts). It is a non contact process that most often uses a CO2 laser that uses pressure and heat to cut or etch parts out of flat pieces of plastics, woods, cardboard, and other materials.

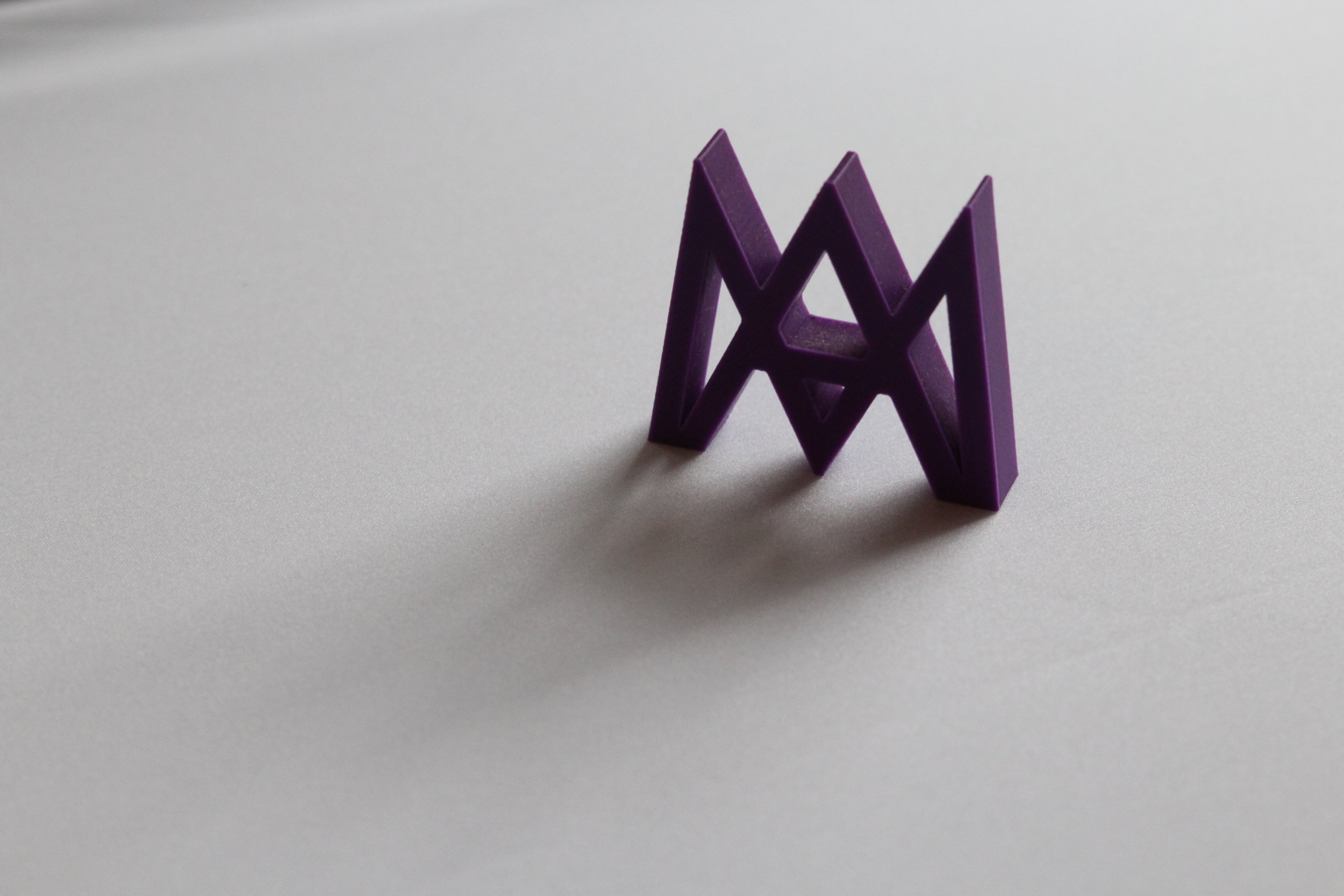

SLS 3D Printing

SLS 3D Printing is a method that uses powdered thermoplastics most notably, nylons. This allows the use of actual plastics like FDM 3D Printing but with higher precision. Layer by layer a laser melts the powder into a part, since each successive layer rests on the previous powder base, supports do not need to be used in this method which makes it more affordable than resins. However, since the parts are made from powder, finished parts tend to have a slightly rough surface akin to extremely fine sandpaper.

CNC Machining

CNC is another subtractive manufacturing process. Completely finished parts can come from a CNC machine. You start with a block of material (all sorts of metals, plastics, etc.) which slowly gets cut down into the shape of the desired piece.

…For Serious Work

Create functional prototypes with all types of 3D Printing, CNC, and Laser Cutting and short-run production in CNC, Injection Molding, Casting, and more. CAD/3D Modeling Services.

…For Serious Work

Create functional prototypes with all types of 3D Printing, CNC, and Laser Cutting and short-run production in CNC, Injection Molding, Casting, and more. CAD/3D Modeling Services.

WHO IS 3D PRINTING AND RAPID PROTOTYPING RIGHT FOR?

Medical

Manufacturing medical supplies can help patients in need. 3D Printing allows customization to fit a patient’s anatomy. We can see this in dental implants, prosthetics, and even scale models that can be created to exact specifications. Most of the medical devices use FDM printing thermoplastics, or metal that can be sterilized by steam autoclave, or gamma radiation. Be it a prototype, prosthetic, or surgical guide, we have you covered.

Mechanical Engineers and Product Designers

Engineers and Product Designers who need to iterate on their designs faster than normal prototyping methods allow them to. 3D Printing/Rapid Prototyping can provide excellent quality in an extremely short amount of time. From early prototyping stages to all the way to the later stages of prototyping. Down from a rough early drafts with FDM prototyping to almost final pieces with SLA prototyping.

Artists

Artists that would like to bring their pieces to life. See your 3D models become actual objects that you can hold and touch. 3D Printing can bring your vision to life with SLA models that will capture every detail no matter how fine it is. From very small 15mm models to extremely big models, from single prototypes to short run production.

Architects And Architectural Firms

Architects who need to produce highly detailed architectural models can use 3D Printing to create an intricate and durable design straight from CAD data, and provide a clear picture of what the final project looks like. With a physical 3D Printed model, you can better engage your clients to understand the project. We can produce simple, complex buildings, structural models, or scaled furniture, in days rather than weeks or months.

Jewelry Designers

Jewelry design and production was defined as an expensive privilege due to its complexity and techniques. However, 3D Printing has changed this concept as now jewelers can produce incredibly difficult and complex designs and geometries. Thanks to a precisely controlled laser, 3D Printing can produce extraordinary details, delicate filigrees, raised text, and detailed pave stone settings, all with amazing sharpness. With castable wax models you can even cast directly off of your 3D Print.

Testimonials

From Past And Present Clients.

Testimonials

From Past And Present Clients.

Some Of Our Past And Present Clients

“I’ve worked with a few 3D printing companies for some functional prints for the office and Obsessively Geek’s customer service and attention to detail stood out. The website was very easy to navigate through and was very informative on his services. I requested a quote on the website, dropped my .STL files, for his reference, and waited for a response back. Obsessively Geek were kind and communicative through the process and were happy to answer any questions I had. About two hours after my initial request, we had spoken on the phone to discuss my needs and shortly afterward he sent me an email with the 3D design, that he custom made, for final confirmation before printing. The final products were shipped quickly and arrived safely packed and in pristine condition. I’ll definitely be a return customer!”

“Obsessively Geek got me the cleanest, highest detail prints I’ve ever seen, and they got it to me within a few days! If you’re looking for rapid, quality prototypes for miniatures or other high-detail models, go to these guys!”

“Awesome! Great communication. Super fast delivery, very accommodating - They totally over-delivered. Thanks!”

“Obsessively Geek did a phenomenal job at a great price. They printed over the weekend, shipped it, and I got the package the following morning. The quality is great and they communicated every step of the way.”

“The amount of detail on this very small print is fantastic. Obsessively Geek was a pleasure to work with. They sent me updates during the printing process, and showed me pictures of my print before shipping it out. I will be placing orders with this company again in the future.”

“Obsessively Geek suggested a more suitable material than what I ordered which really helped. They kept me informed every step of the way. They’re great to work with.”

“Service is great, prices are reasonable, I absolutely recommend Obsessively Geek.”

“Obsessively Geek is a fast, responsive and responsible company, one that you can rely on every time. Thanks for the work.”

“Great company. They went above and beyond to get my print done. Will order again.”

“Great prints! Awesome communication! Highly recommended!”

Get A Quote Now!

Upload your files below for an instant quote and one of our representatives will get back to you shortly!

Get A Quote Now!

Upload your files below for an instant quote and one of our representatives will get back to you shortly!